In the rapidly evolving manufacturing landscape, the demand for precision metal parts continues to surge, driven by advancements in technology and the need for enhanced performance across various industries. According to a recent report by MarketsandMarkets, the global precision metal parts market is projected to grow from $92.3 billion in 2020 to $115.4 billion by 2025, highlighting the critical role these components play in achieving optimal operational efficiency.

As manufacturers strive for higher accuracy and reliability, selecting the right precision metal parts becomes imperative. This blog explores the top five comparisons of the best precision metal parts, designed to empower manufacturers in making informed decisions that align with their performance goals and quality standards.

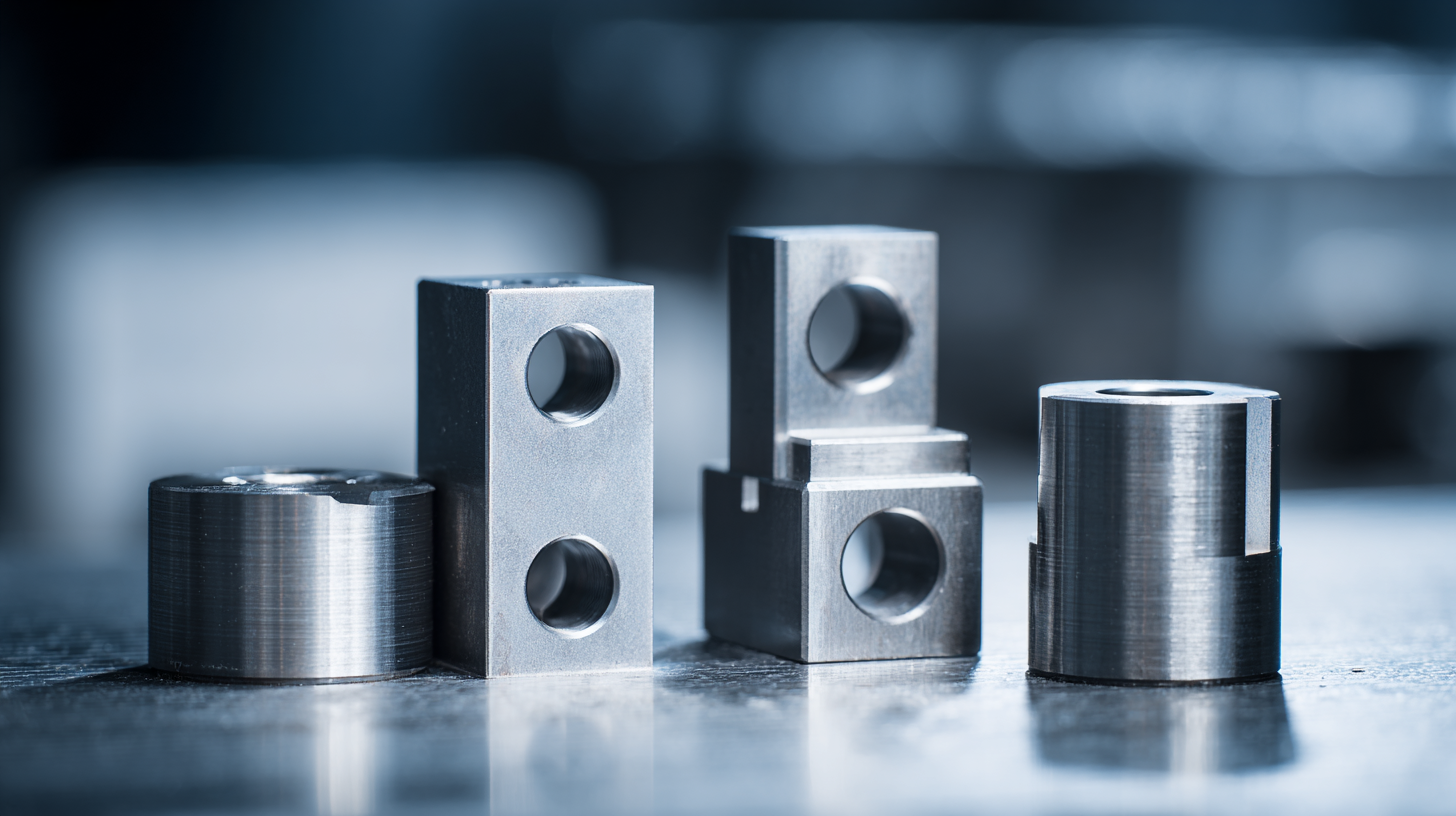

Precision metal parts have become increasingly vital in enhancing manufacturing efficiency across various industries. The global sheet metal processing equipment market is projected to grow significantly, reflecting the rising demand for high-quality and durable parts. By utilizing precision metal components, manufacturers can achieve higher accuracy, reduce waste, and improve overall productivity. These benefits are critical in competitive markets where optimization and reliability are paramount.

In addition to traditional machining technologies, innovations such as laser processing are transforming manufacturing, particularly in medical device production. The integration of lasers allows for intricate designs and precision cuts that meet stringent safety standards. Similarly, 3D printing is revolutionizing automotive manufacturing by enabling rapid prototyping and customization of parts. This technology facilitates on-demand production, minimizing inventory costs and allowing for a more agile response to changing market needs. Adopting these advanced manufacturing methods ensures that companies can maintain efficiency while delivering high-performance products.

| Feature | Metal Type | Precision Level (µm) | Cost ($/part) | Applications |

|---|---|---|---|---|

| Machined Parts | Aluminum Alloy | 10 | 5.00 | Aerospace, Automotive |

| Stamped Parts | Stainless Steel | 15 | 3.50 | Electronics, Medical Devices |

| Cast Parts | Copper Alloy | 20 | 7.00 | Electrical Components, Plumbing |

| 3D Printed Parts | Titanium | 25 | 150.00 | Medical Implants, Aerospace |

| Forged Parts | Carbon Steel | 5 | 10.00 | Heavy Machinery, Automotive |

In the realm of manufacturing, the choice of precision metal parts significantly influences overall performance. Key characteristics of these top components include dimensional accuracy, surface finish, and material strength. A recent report by the International Journal of Advanced Manufacturing Technology noted that precision parts manufactured with tolerances within ±0.005 mm can enhance product functionality by up to 30%. This level of precision not only reduces the likelihood of failures but also ensures optimal machining efficiency.

When selecting precision metal parts, consider these tips: First, assess the material properties such as tensile strength and corrosion resistance, as they determine the part's longevity and reliability in high-stress environments. Second, prioritize suppliers who utilize advanced processes like CNC machining and additive manufacturing, which can guarantee higher precision levels. It's essential to verify not just the specifications but also the quality certifications of your supplier, as those with ISO 9001 certification typically exhibit superior quality control practices.

Lastly, keep an eye on the surface finish of the parts. Parts with a fine surface finish can effectively reduce friction and wear, enhancing the overall lifespan of components. According to a survey by the Society of Manufacturing Engineers, parts with excellent surface finishes can improve assembly efficiency by up to 25%, making them a critical factor in high-performance manufacturing.

When it comes to manufacturing precision metal parts, the choice of material is crucial for ensuring optimal performance. Commonly used materials include stainless steel, aluminum, and titanium, each offering unique advantages and disadvantages. Stainless steel is favored for its corrosion resistance and strength; however, it can be heavier and less malleable compared to alternatives. Aluminum, on the other hand, is lightweight and has excellent machinability, making it ideal for high-speed applications, but it may not withstand extreme temperatures as effectively as titanium.

**Tip:** When selecting materials, consider the specific requirements of your application. For instance, if the parts will be exposed to harsh environments, prioritize corrosion-resistant materials like stainless steel.

Another critical aspect of material comparison is the fabrication process. Techniques such as CNC machining, 3D printing, and die casting can influence the final product's precision and durability. For instance, CNC machining is known for producing highly detailed components with tight tolerances, which is essential in many demanding sectors.

**Tip:** Always evaluate the cost-effectiveness of each process in conjunction with the materials chosen. Sometimes, opting for a less expensive material incorrectly paired with a high-precision process could result in an overall increase in production costs.

Precision metal parts play a crucial role in optimizing manufacturing processes, and their impact on production cost reduction cannot be overstated. According to a report by the Manufacturing Institute, companies that invest in precision engineering technologies can see a reduction in production costs by up to 30%. This is achieved through enhanced accuracy, minimizing material waste, and reducing the need for rework, all of which contribute to more efficient operations. With the industry moving towards more automated processes, precision metal components are essential for maintaining high standards while keeping costs manageable.

Furthermore, a study by Grand View Research indicates that the global precision metal parts market is projected to reach $233.2 billion by 2025, highlighting an increasing demand for these components due to their cost-effectiveness. By leveraging advanced manufacturing techniques such as CNC machining and additive manufacturing, manufacturers can create parts that not only meet stringent quality requirements but also help in lowering overhead costs. The use of precision metal parts thus not only enhances product quality but also directly influences the bottom line, empowering manufacturers to remain competitive in a rapidly evolving market.

When it comes to optimizing product quality in manufacturing, selecting the right precision metal parts is crucial. According to a report from the Precision Metalforming Association, industries that prioritize precision components see a significant reduction in failure rates—up to 30% lower in many cases. This enhanced reliability not only improves end-user satisfaction but also reduces costly downtime during production.

Moreover, advancements in manufacturing technologies, such as additive manufacturing and CNC machining, have revolutionized the options available for precision metal parts. A study from Grand View Research indicates that the global precision metal part market is projected to reach $1.6 billion by 2025, driven largely by the demand for increased efficiency and performance in various sectors, including automotive and aerospace. By investing in high-quality precision parts tailored to specific applications, manufacturers can achieve optimal performance, thereby enhancing overall product quality.

This chart compares the performance metrics of five types of precision metal parts, focusing on factors such as tensile strength, corrosion resistance, and dimensional accuracy.