In today's fast-paced manufacturing landscape, the importance of selecting the right CNC Machining Center cannot be understated. As China continues to elevate its manufacturing capabilities and pursue quality upgrades, businesses worldwide are keenly attuned to the advantages that cutting-edge CNC technology offers. This blog will guide you through the critical factors to consider when choosing the best CNC Machining Center for your specific manufacturing needs. From precision and versatility to cost-effectiveness and support services, understanding these elements can significantly impact your production efficiency and output quality. Join us as we explore how the right CNC Machining Center can not only enhance your manufacturing process but also help your products succeed in the global market.

When selecting a CNC machining center, it is crucial to first understand your specific manufacturing requirements. The global market for CNC vertical machining centers is projected to grow significantly, with an estimated increase of USD 1,130.34 million from 2022 to 2027. This growth is primarily driven by advancements in manufacturing processes within the industrial machinery sector. As such, businesses should clearly define their operational needs, focusing on aspects such as production volume, material types, and part complexity.

Additionally, the expansion of the machine tools market, which is expected to rise from USD 97.1 billion in 2024 to a staggering USD 196 billion by 2034, indicates a robust demand for versatile and efficient machining solutions. Companies looking to invest in CNC technology should consider advanced features like enhanced process damping and 5-axis capabilities, which allow for greater precision and flexibility in production. As artificial intelligence continues to shape the evolution of machining, integrating intelligent systems can significantly enhance productivity and optimize manufacturing workflows. Understanding these dynamics will help manufacturers make informed decisions when choosing the right CNC machining center to meet their unique demands.

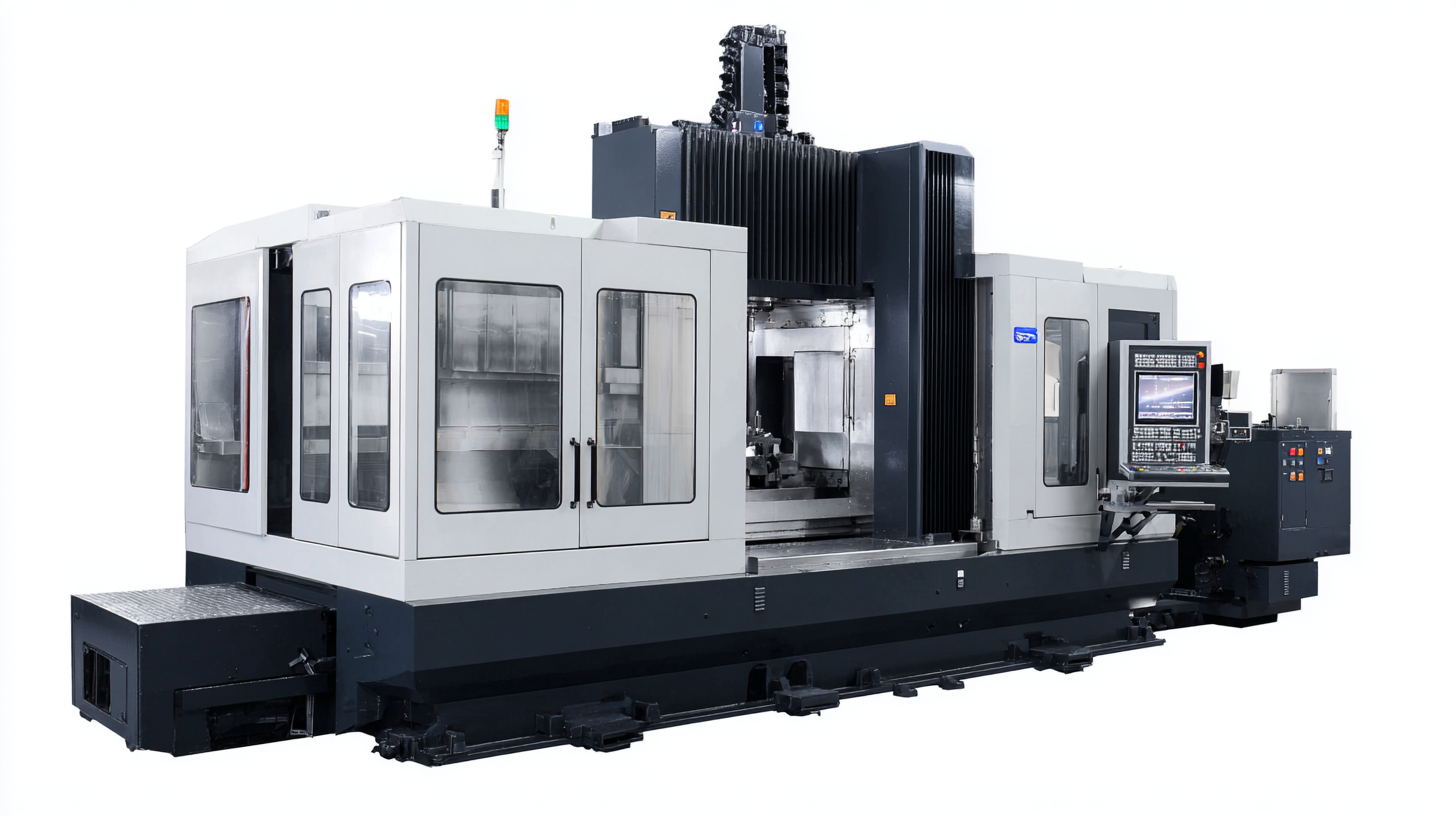

When selecting a CNC machining center for your manufacturing needs, it’s crucial to focus on several key features that can significantly impact productivity and efficiency. One of the first considerations should be the machine’s size and layout. Assessing the physical space available in your workshop helps determine the dimensions of the equipment. Additionally, a larger machining center may offer more versatility for complex parts, while compact models can provide a cost-effective solution for smaller components.

Another vital feature to evaluate is the spindle speed and power. The spindle speed affects how quickly and efficiently the machine can create parts, which is instrumental in meeting tight production deadlines. Opting for a machining center with higher horsepower can enhance cutting performance, especially for tougher materials. Furthermore, consider the availability of automation options. Incorporating features such as robotic loading and unloading can streamline processes, reduce labor costs, and improve overall output. Balancing these factors will guide you in selecting the most suitable CNC machining center for your specific manufacturing applications.

The landscape of CNC machining technologies has evolved dramatically, with several options available to manufacturers today, each tailored to specific applications. Technologies such as vertical machining centers, horizontal machining centers, and multi-axis systems serve different purposes, impacting production efficiency and product quality. According to a recent industry report, adopting advanced CNC technologies can enhance productivity by up to 30%, significantly reducing cycle times and minimizing errors that often occur in manual machining processes.

Vertical machining centers are particularly suited for precision parts and complex geometries, making them a popular choice in the automotive and aerospace sectors. In contrast, horizontal machining centers are favored for their ability to handle larger workpieces and reduce setup times, which is crucial for high-volume production runs. Multi-axis machining offers even greater flexibility, allowing for intricate designs and improved surface finishes. Data from market analyses indicate that manufacturers utilizing multi-axis CNC systems have realized up to a 50% increase in throughput, showcasing the transformative impact of selecting the right machining technology on operational efficiency and product output.

When selecting the best CNC machining center for your manufacturing needs, evaluating

software and automation capabilities

is crucial. As automation technology evolves, integration of advanced software with CNC machines

enhances efficiency and precision. Recent trends highlight that advanced simulation software is

increasingly adopted for real-time visualizations, aiding operators in optimizing machining

processes while reducing errors. Such tools play a vital role in shaping the future of manufacturing,

particularly in enhancing part accuracy and streamlining workflows.

Tip: Consider investing in CNC machines that come equipped with

comprehensive software solutions,

as they allow seamless integration and better control over the manufacturing process.

Moreover, the introduction of capabilities beyond traditional machining, such as

friction stir welding, exemplifies how advanced CNC centers

can meet diverse manufacturing requirements. Automation not only boosts throughput but also

allows manufacturers to support higher-volume production needs effectively. Embracing such

technological advances not only drives productivity but also contributes to overall quality and sustainability

in manufacturing practices.

Tip: Look for CNC centers that feature

modular automation options,

providing flexibility to adapt to various production scales and complexities.

When selecting a CNC machining center, evaluating the maintenance and support services offered by suppliers is crucial for ensuring long-term operational efficiency. A well-performing CNC machine is an investment, and to protect this investment, it's essential to have a robust support system in place. Examine the maintenance programs provided by potential suppliers, including routine inspections, availability of replacement parts, and response times for service calls. A supplier that offers comprehensive maintenance plans can mitigate downtime and extend the lifespan of your machinery.

Additionally, consider the accessibility of technical support. Suppliers should provide assistance not only during installation but throughout the entire lifecycle of the machining center. This includes training for your operators and readily available troubleshooting assistance. A supplier with a solid reputation for customer support can significantly enhance your manufacturing process, allowing your team to quickly resolve issues and optimize productivity. Choosing a supplier that prioritizes ongoing support will ensure that your CNC machining center operates at peak performance, ultimately contributing to your success in today's competitive market.