In today’s competitive landscape, the demand for high-quality Metal Fabrication Parts continues to grow, driven by significant advancements in manufacturing technologies and a surge in industries such as automotive, aerospace, and construction. According to a recent report from Research and Markets, the global metal fabrication market is projected to reach USD 19.76 billion by 2026, expanding at a compound annual growth rate (CAGR) of 3.2% from 2021. This growth underscores the increasing reliance on precisely engineered metal components that offer enhanced durability, versatility, and efficiency.

As manufacturers navigate the complexities of modern production, understanding the compelling advantages of Metal Fabrication Parts becomes crucial in meeting evolving consumer demands, optimizing operational costs, and driving innovation across various sectors.

Metal fabrication plays a vital role across various industries, demonstrating its impressive versatility and adaptability. According to a report by IBISWorld, the metal fabrication market in the U.S. is expected to reach over $112 billion by 2025. This growth underscores the increasing reliance on metal parts, which are crucial in sectors such as automotive, aerospace, and construction. The precision and durability of fabricated metal components enhance product lifespan and performance, making them a preferred choice in high-demand applications.

In the automotive industry alone, metal fabrication contributes significantly to both innovation and efficiency. A study by MarketsandMarkets indicates that the automotive metal fabrication market is projected to grow from $37.98 billion in 2020 to $52.39 billion by 2025, driven by advancements in lightweight materials and sustainable manufacturing processes. Additionally, sectors like energy and electronics also harness the flexibility of metal fabrication techniques, allowing custom solutions that meet strict regulatory standards and evolving consumer needs. As industries continue to evolve, the diverse applications of metal fabrication signal a robust future for this essential manufacturing process.

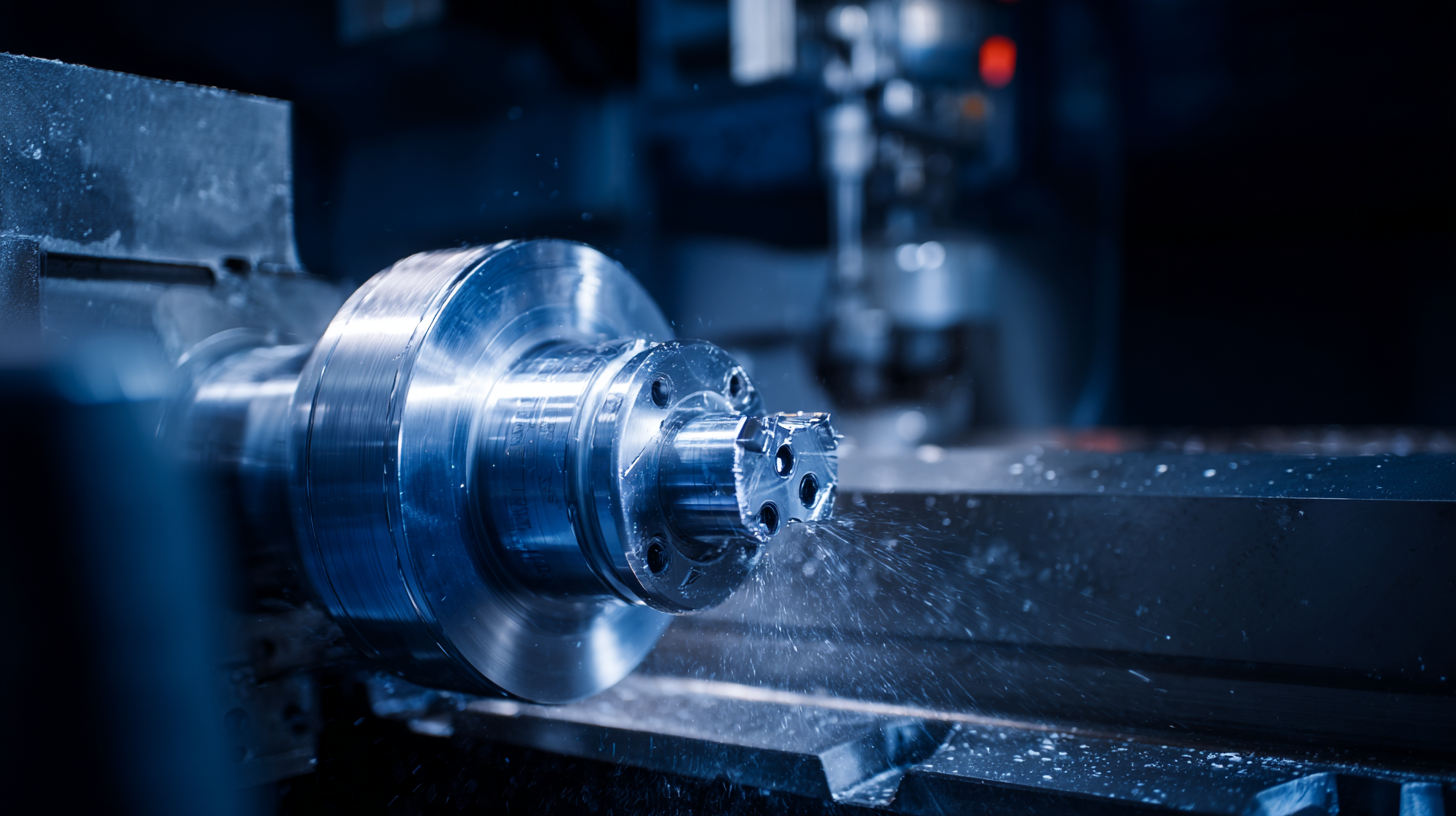

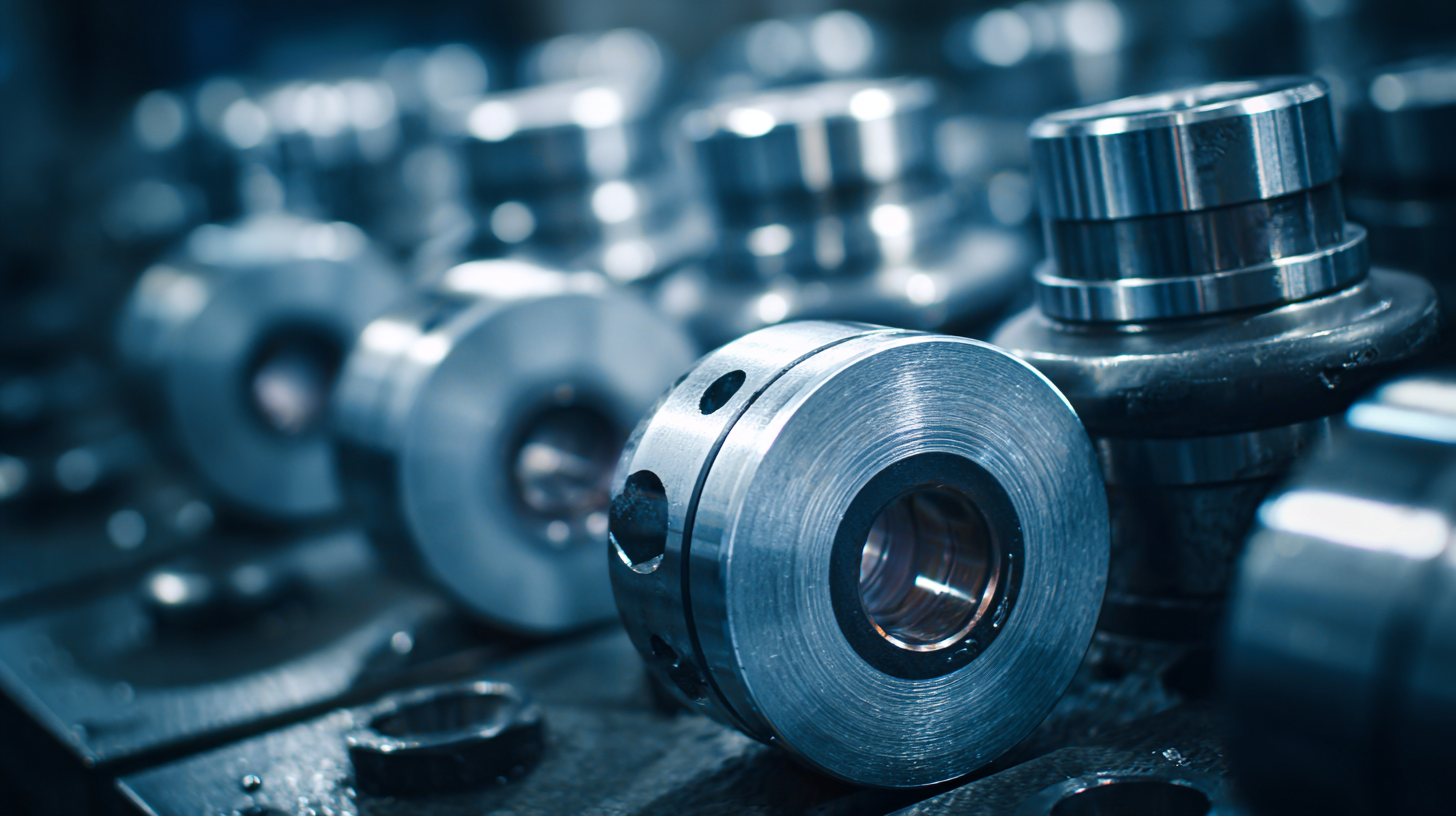

In today’s competitive landscape, high precision and customization are two critical factors that make metal fabrication parts particularly appealing. Industries ranging from aerospace to automotive demand components that meet exact specifications to ensure optimal performance and safety. Advanced fabrication techniques, such as laser cutting and CNC machining, allow manufacturers to produce parts with tight tolerances, ensuring that they fit perfectly within their designated systems. This precision minimizes the risk of mechanical failure and enhances the overall reliability of the end product.

Customization plays a vital role in addressing the unique needs of various industries. Metal fabrication enables the creation of bespoke parts tailored to specific applications, allowing companies to innovate without the constraints typically associated with mass-produced components. From unique geometries to specialized materials, the ability to customize parts not only enhances functionality but also allows for aesthetic considerations that can set a company apart in a crowded marketplace. As businesses seek to differentiate themselves, the advantages of personalized metal fabrication remain undeniable.

In today's competitive landscape, the cost-effectiveness of metal fabrication stands out as a pivotal factor for large-scale production. The integration of advanced manufacturing technologies, such as additive manufacturing, has greatly enhanced efficiency and reduced costs. For instance, the shift from traditional prototyping to Metal Big Area Additive Manufacturing (MBAAM) allows for the swift production of complex structures, enabling businesses to keep pace with evolving market demands while minimizing material wastage.

Tips: When considering metal fabrication for your production needs, focus on scalability. Evaluate how your chosen fabrication method can adapt to increasing demands without compromising quality. Additionally, keep an eye on emerging technologies that could streamline your process, as the industry is rapidly evolving.

Moreover, the recent advancements in automated manufacturing and stress prediction methods highlight the importance of staying updated with industry innovations. These techniques not only improve the reliability of fabricated parts but also contribute to reducing overall production costs, keeping your operations competitive.

Tips: Collaborate with suppliers who are invested in innovation to ensure you leverage the latest developments in fabrication technologies. This partnership can lead to cost savings and enhanced product quality, reinforcing your position in the market.

The landscape of metal fabrication is undergoing a significant transformation, driven by innovative technologies that are redefining how parts are created and utilized. Advancements such as additive manufacturing, robotics, and automation have streamlined processes, enabling manufacturers to produce complex geometries with precision and efficiency. This innovation not only reduces production times but also minimizes waste, making it an environmentally friendly approach. The integration of smart technologies, such as IoT and AI, allows for real-time monitoring and predictive maintenance, enhancing overall productivity.

Moreover, innovation in materials science has paved the way for the use of advanced alloys and composites that enhance durability and performance. These cutting-edge materials are designed to withstand extreme conditions, thereby expanding the applications of metal fabrication parts across various industries—from aerospace to automotive. As companies increasingly seek to differentiate themselves in a competitive market, the adoption of these innovative practices in metal fabrication will undoubtedly continue to play a pivotal role in ensuring they stay ahead of the curve. The role of innovation is not just about keeping pace with industry demands; it’s about paving the way for a more efficient and sustainable future in metal fabrication.

In today's environmentally conscious market, sustainability and eco-friendliness play crucial roles in manufacturing practices, and metal fabrication is no exception. The industry has made significant strides in adopting green practices that not only reduce waste but also minimize the carbon footprint. Recyclable materials such as steel and aluminum are often used, allowing for the production of parts that can be reused and repurposed, contributing to a circular economy. This emphasis on recycling aligns with global sustainability goals and attracts businesses that prioritize responsible sourcing.

Moreover, advancements in technology have enhanced the efficiency of metal fabrication processes, leading to lower energy consumption and reduced emissions. Techniques such as automated waterjet cutting and laser fabrication consume less energy and produce less waste compared to traditional methods. By implementing energy-efficient machinery and practices, fabricators can significantly reduce their environmental impact while maintaining high quality and precision in their products. As industries increasingly seek sustainable solutions, metal fabrication stands out as a forward-thinking option, championing eco-friendly practices that resonate with the values of modern consumers.

| Reason | Description | Environmental Impact | Economic Benefits |

|---|---|---|---|

| 1. Recyclability | Metals can be recycled infinitely without degradation. | Reduces landfill waste and conserves natural resources. | Lower production costs and use of recycled materials. |

| 2. Longevity | Metal parts are durable and have a long lifecycle. | Minimizes the need for replacements, thereby reducing waste. | Reduces overall maintenance and replacement costs. |

| 3. Energy Efficiency | Manufacturing processes have become more energy-efficient. | Decreases carbon footprint during production. | Lowers production expenses through reduced energy consumption. |

| 4. Reduced Waste Generation | Modern fabrication techniques minimize material waste. | Supports responsible environmental stewardship. | Maximizes yield from materials, increasing profit margins. |

| 5. Innovative Solutions | Advancements in fabrication lead to smarter, eco-friendly designs. | Promotes the development of sustainable products. | Encourages market differentiation and competitiveness. |