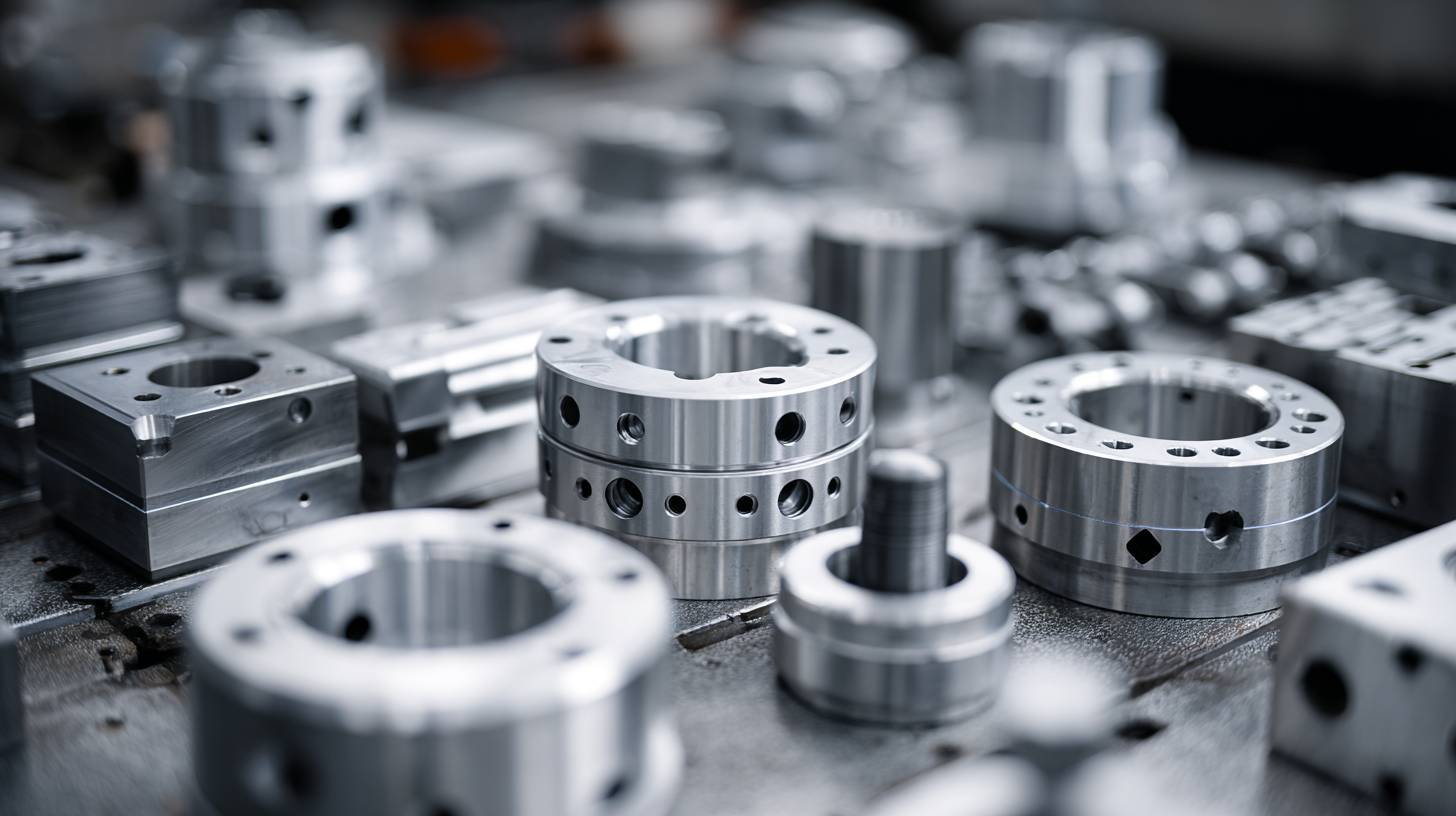

In today's rapidly evolving manufacturing landscape, Aluminum CNC Machining Parts have emerged as crucial components across various industries, including automotive, aerospace, and electronics. According to a recent market analysis by MarketWatch, the global CNC machining market is projected to reach $100 billion by 2026, with aluminum parts driving a significant portion of this growth due to their lightweight, durability, and excellent corrosion resistance. As industries strive for precision and efficiency, the demand for high-quality aluminum components is surging, emphasizing the need for manufacturers to identify reliable and skilled suppliers. This blog will explore the distinct features and applications of the best aluminum CNC machining parts, providing insights on how to effectively evaluate and select suppliers in this competitive market.

Aluminum is a favored material in CNC machining due to its unique properties, including lightweight, corrosion resistance, and excellent thermal conductivity. These characteristics not only enhance the performance of the machined parts but also significantly impact the efficiency of the CNC machining process itself. The ability to easily cut and shape aluminum allows manufacturers to produce intricate designs while maintaining precision, resulting in high-quality components across various industries.

Aluminum is a favored material in CNC machining due to its unique properties, including lightweight, corrosion resistance, and excellent thermal conductivity. These characteristics not only enhance the performance of the machined parts but also significantly impact the efficiency of the CNC machining process itself. The ability to easily cut and shape aluminum allows manufacturers to produce intricate designs while maintaining precision, resulting in high-quality components across various industries.

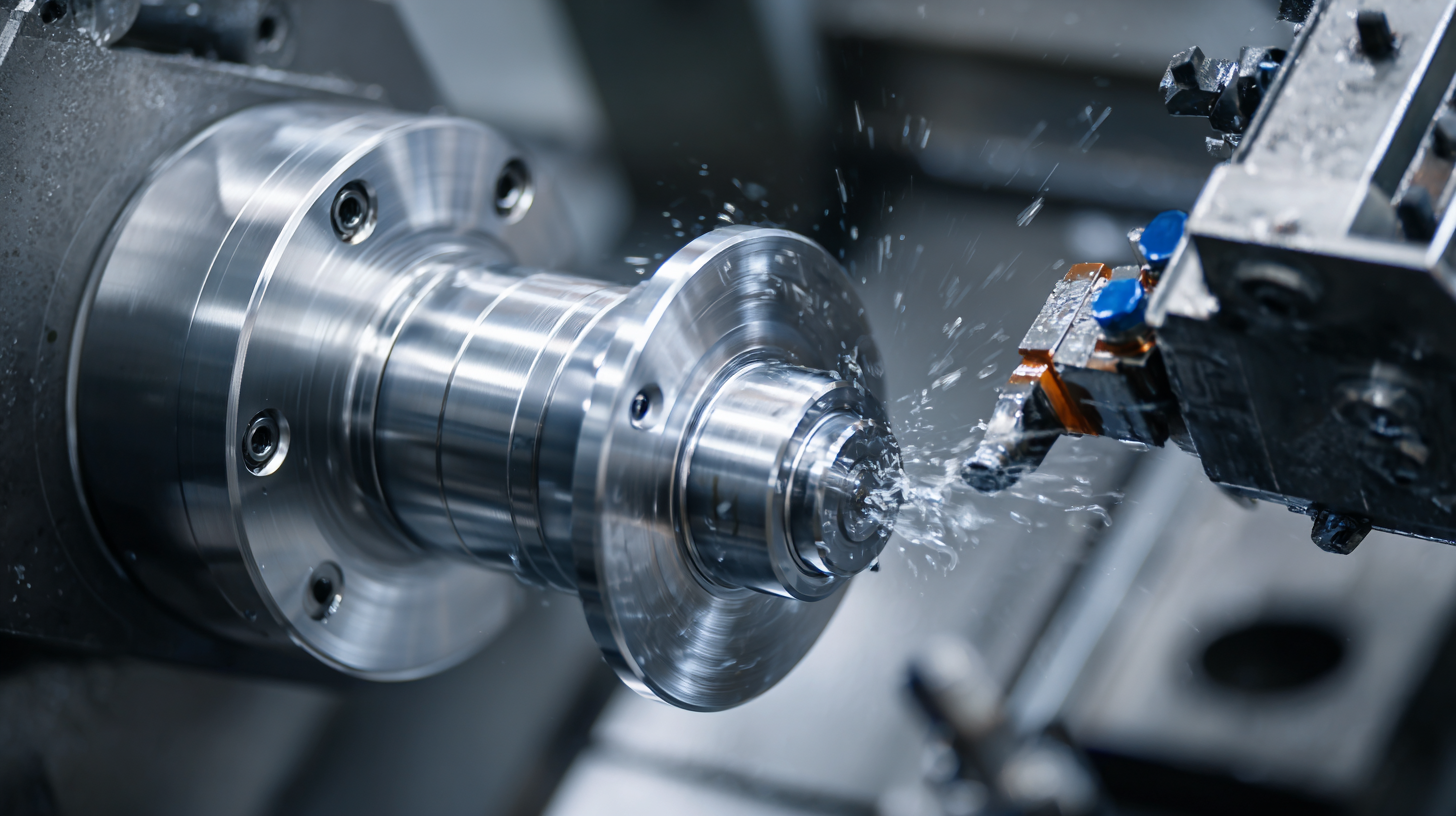

When working with aluminum in CNC machining, it is essential to consider the tooling materials and techniques used. For optimal efficiency, carbide tools are recommended as they provide excellent wear resistance, permitting higher cutting speeds and longer tool life. Additionally, employing the right coolant can help maintain tool integrity and improve surface finish by reducing heat buildup during machining.

Another important tip is to adjust the feed rates appropriately. Aluminum can be machined quickly compared to other metals; however, overly aggressive feed rates can lead to poor surface quality and increased tool wear. Strike a balance between speed and precision to ensure the longevity of both the tools and the parts being produced. With these considerations in mind, manufacturers can maximize the advantages of aluminum in CNC machining, catering to the diverse needs of industries like aerospace, automotive, and electronics.

Aluminum CNC machining components have become integral across various industries due to their lightweight, corrosion resistance, and excellent machining characteristics. One key industry benefiting from these parts is the aerospace sector. Here, the demand for precision and lightweight materials significantly drives the use of aluminum CNC components to optimize fuel efficiency and enhance performance. Aircraft manufacturers rely on these machined parts for everything from structural components to intricate engine components, ensuring robust designs without the added weight.

Another crucial industry is automotive manufacturing. With the increasing push for electric vehicles and fuel efficiency, aluminum CNC parts are critical in reducing vehicle weights and improving energy efficiency. These components can be found in chassis, body panels, and engine parts, highlighting the versatility and durability of aluminum.

Tip: When selecting aluminum CNC machining parts, consider factors such as the specific grade of aluminum to be used, as different grades offer varied strength and corrosion resistance. Additionally, always ensure to work with a reputable CNC machining service to guarantee precision and quality in the final products. This will significantly impact performance and durability across applications.

When comparing aluminum with other materials in CNC machining, several distinctive features set aluminum apart. One of the most significant advantages of aluminum alloys is their excellent machinability, which often leads to faster production times and lower tool wear. For instance, studies show that aluminum alloys can be machined at speeds up to 10 times faster than steel, enhancing productivity in various industries such as aerospace and automotive. The lightweight nature of aluminum also contributes to reduced energy consumption in applications ranging from turbo machinery components to intricate parts for electronic devices.

**Tips:** When selecting materials for CNC machining, consider the specific needs of your project—lighter materials like aluminum can contribute to energy savings and improved performance in weight-sensitive applications. Additionally, keep in mind that while aluminum is often easier to work with, its thermal conductivity allows for efficient heat dissipation during machining, which can be a critical factor in maintaining tool integrity and prolonging longevity.

Moreover, aluminum's resistance to corrosion makes it an ideal choice for industries that require durability in challenging environments. In a comparative analysis, it is vital to assess not only the mechanical properties but also how each material responds to machining processes. For example, while steel may offer higher tensile strength, the trade-offs in weight and machinability can significantly affect overall performance and cost-effectiveness. Such insights are crucial for manufacturers looking to leverage the benefits of aluminum in their CNC machining applications.

| Feature/Aspect | Aluminum | Steel | Plastic | Titanium |

|---|---|---|---|---|

| Weight | Lightweight | Heavy | Lightweight | Heavyweight |

| Corrosion Resistance | High | Medium | Low | High |

| Thermal Conductivity | Excellent | Moderate | Low | Good |

| Cost | Moderate | Moderate | Low | High |

| Machinability | Excellent | Good | Excellent | Moderate |

In modern manufacturing, aluminum CNC machined parts have become pivotal due to their lightweight yet durable characteristics, particularly in industries such as aerospace and automotive. The versatility of aluminum allows for innovative applications, including complex geometries and enhanced performance metrics. As additive manufacturing continues to gain traction, particularly with predictions that by 2030 the 3D printing industry will surpass a valuation of $40 billion, integrating aluminum CNC machining with additive technologies can lead to significant advances in efficiency and sustainability.

Recent advancements in CNC machining technologies have improved the precision and efficiency of manufacturing processes by optimizing milling parameters, making it crucial in high-demand environments. For instance, high-speed machining offers notable enhancements in operational performance, which is vital for the aerospace sector where weight reduction and strength are critical. Furthermore, the evolving landscape of composite materials presents unique opportunities for aluminum CNC machined parts, aligning with the industry’s trend towards producing lighter, more efficient components that adhere to sustainable development goals.

As China's manufacturing landscape evolves, aluminum CNC machining is set to play a pivotal role in various industries. According to a report by Mordor Intelligence, the global CNC machining market is projected to reach USD 100 billion by 2025, with a significant portion attributed to advancements in aluminum machining technologies. This trend reflects the growing demand for lightweight, durable materials across sectors such as aerospace, automotive, and electronics—areas where aluminum components offer distinct advantages.

One of the most notable future trends in aluminum CNC machining in China is the increasing integration of automation and artificial intelligence. A report from ResearchAndMarkets indicates that the adoption of AI-driven CNC machinery could enhance production efficiency by up to 30%. Furthermore, as manufacturers strive for sustainability, the shift towards eco-friendly processes in aluminum machining is becoming more prevalent. This includes the implementation of recycling technologies that reduce waste, aligning with global sustainability goals.

As these trends develop, aluminum CNC machining in China is poised for unprecedented growth, offering innovative solutions to meet the demands of a rapidly changing industrial landscape.