In today’s global supply chain landscape, the selection of high-quality metal parts is crucial for maintaining competitive advantage and ensuring product efficiency. According to a report by the International Federation of Robotics, the demand for precision-engineered metal parts has surged by over 10% annually, reflecting the rapid advancements in automation and manufacturing technologies (IFR, 2022). A well-chosen metal part can significantly influence product integrity, operational costs, and time-to-market.

However, navigating the complexities of sourcing from diverse suppliers across various regions requires a strategic approach that considers both quality and sustainability. Given the increasing importance of sustainability and supply chain resilience, understanding the factors that contribute to the optimal selection of metal parts is essential for manufacturers looking to thrive in a highly competitive global market.

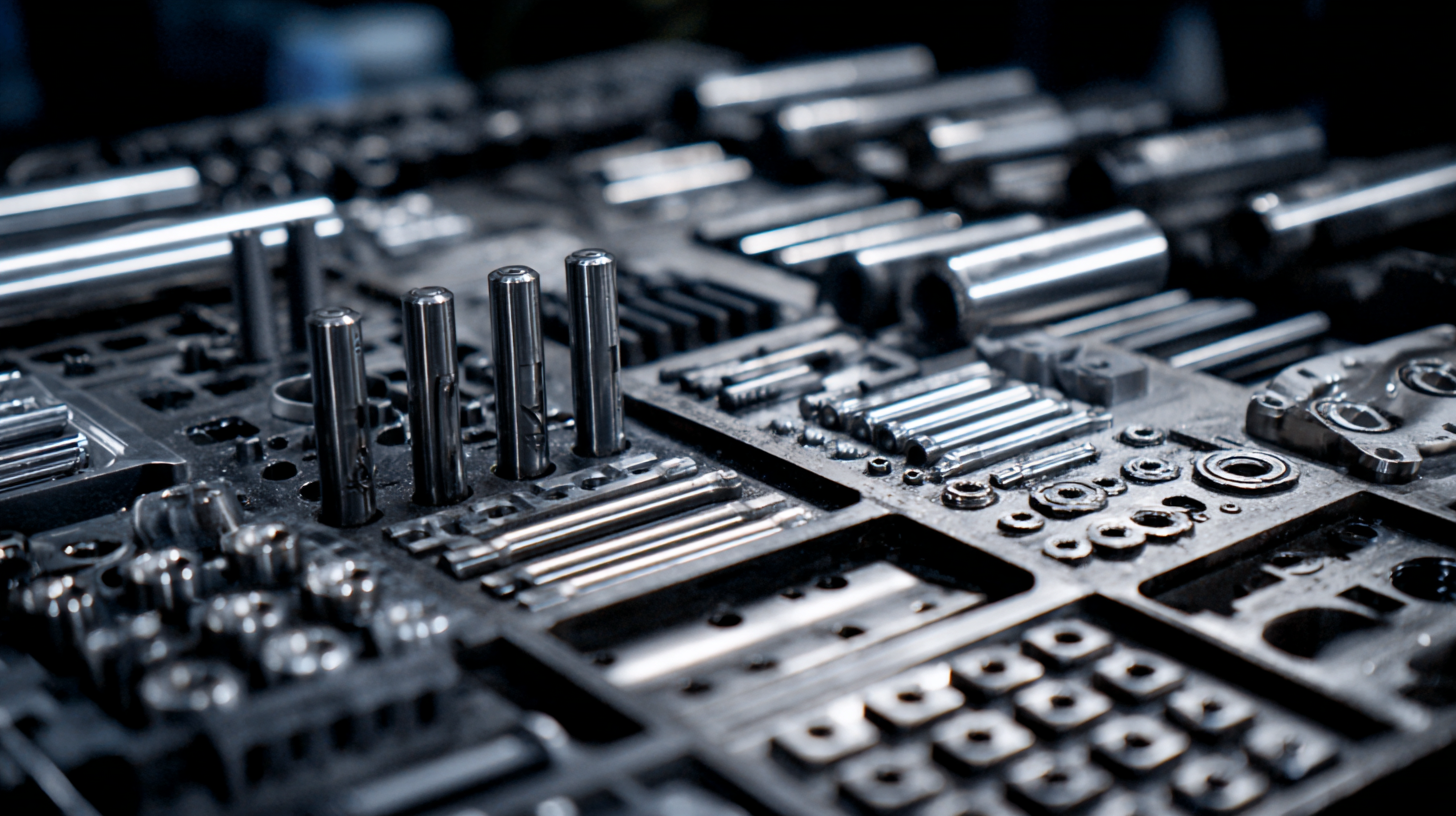

In today's global supply chains, the significance of metal parts cannot be overstated. These components form the backbone of countless industries, from automotive to aerospace, playing a pivotal role in ensuring the durability and reliability of final products. Understanding the types of metal parts required is essential for optimizing production processes and meeting the demands of diverse markets. Quality metal parts can enhance not only the performance but also the safety and lifespan of products, rendering them a critical consideration for manufacturers.

The selection of appropriate metal parts for a global supply chain goes beyond mere functionality. It involves evaluating factors such as material properties, cost-effectiveness, and supplier reliability. Engaging with suppliers who understand international standards and can provide consistent quality across borders is crucial. By prioritizing these elements, businesses can mitigate risks associated with supply chain disruptions and ensure that they remain competitive in an increasingly complex marketplace. Strategically sourcing metal parts is thus an investment in both product integrity and long-term success.

When selecting the best metal parts for your global supply chain, several key factors come into play. The material type is paramount, as different applications require distinct properties, such as strength, corrosion resistance, and weight. For instance, stainless steel is favored for its durability in harsh environments, while aluminum is often chosen for its lightweight nature. Understanding the specific needs of your products, from automotive components to industrial applications, will guide your choice of materials effectively.

Another critical consideration is the manufacturing process. Techniques such as powder bed fusion and sheet metal fabrication influence the final part's quality and performance. Innovations in additive manufacturing, such as 3D printing, are reshaping how metal parts are produced, enabling complex geometries and reduced material waste. Assessing the capabilities and limitations of different manufacturing methods ensures that you select parts that meet both your design specifications and production efficiency, ultimately enhancing your supply chain resilience.

| Criteria | Importance Level | Common Materials | Applications |

|---|---|---|---|

| Material Quality | High | Aluminum, Steel, Titanium | Aerospace, Automotive |

| Cost | Medium | Stainless Steel, Carbon Steel | Construction, Manufacturing |

| Availability | High | Aluminum, Brass | Consumer Electronics, Furniture |

| Environmental Compliance | High | Recycled Steel, Aluminum | Renewable Energy, Green Building |

| Lead Time | Medium | Copper, Steel | Industrial Equipment, Machining |

When selecting metal parts for a global supply chain, understanding the quality standards and certifications in metal manufacturing is crucial. Different regions and industries adhere to specific standards, such as ISO certifications, ASTM specifications, or industry-specific criteria. These standards ensure that the metal components meet safety, reliability, and performance requirements. For instance, ISO 9001 certification demonstrates a commitment to quality management systems, while ASTM standards provide guidelines for materials and testing methodologies. Companies must familiarize themselves with these certifications relevant to their industry to guarantee that their suppliers can deliver reliable and durable products.

Furthermore, assessing a supplier’s quality control processes is essential in ensuring that the metal parts meet the required standards consistently. This includes understanding their material sourcing, manufacturing techniques, and testing protocols. A robust quality management system implemented by the supplier not only minimizes the risk of defects but also enhances overall supply chain efficiency. Businesses should prioritize suppliers who visibly demonstrate adherence to quality standards and maintain proper documentation, as this transparency builds trust and contributes to smoother operations in the global market. By focusing on quality certifications and supplier practices, companies can optimize their supply chains and reduce risks associated with subpar metal parts.

In today's competitive global market, leveraging China's manufacturing capabilities can provide companies with a significant advantage in sourcing metal parts. According to a report from the McKinsey Global Institute, China accounts for over 28% of global manufacturing output, making it the world’s largest manufacturing hub. This scale enables firms to benefit from lower production costs and shorter lead times, which are essential for maintaining a responsive supply chain.

Furthermore, advancements in technology and infrastructure within China have dramatically improved the quality and efficiency of metal parts production. The World Bank notes that China's logistics performance ranks among the best globally, allowing for timely shipments and fewer disruptions. Companies that strategically partner with Chinese manufacturers can take advantage of these efficiencies while also accessing a workforce skilled in advanced manufacturing techniques. By harnessing these capabilities, businesses can enhance their competitive edge, reduce costs, and ensure the reliability of their supply chain operations.

When it comes to sourcing metal parts for a global supply chain, effective management strategies are crucial to maintaining quality and cost-efficiency. A study by Mordor Intelligence indicates that the global metal parts market is expected to grow at a CAGR of 5.23% between 2021 and 2026. This growth is driven by increasing demand across industries such as automotive, aerospace, and construction, emphasizing the importance of selecting the right suppliers who can meet specific needs while adhering to international standards.

One effective sourcing strategy is to leverage technology such as data analytics and supply chain management software. According to a report by Deloitte, companies that utilize advanced analytics for supplier selection see improvements in supplier performance by up to 20%. This highlights the need for organizations to not only assess cost factors but also consider a supplier's compliance with environmental regulations and their ability to deliver on time.

Additionally, establishing strong partnerships with suppliers can facilitate better communication and lead to innovative solutions that enhance the overall supply chain efficiency.